The relentless demand for precision and repeatability in complex part manufacturing has elevated the importance of stringent quality assurance protocols for CNC milling machines. The Kaibo CNC GJ1417 high-performance gantry CNC milling machine exemplifies industry excellence by integrating over 70 exhaustive factory inspection checkpoints, underpinned by an ISO9001 certified quality management system. This rigorous testing regimen ensures not only superior machining accuracy but also robust operational reliability, minimizing downtime and enhancing throughput for manufacturing enterprises worldwide.

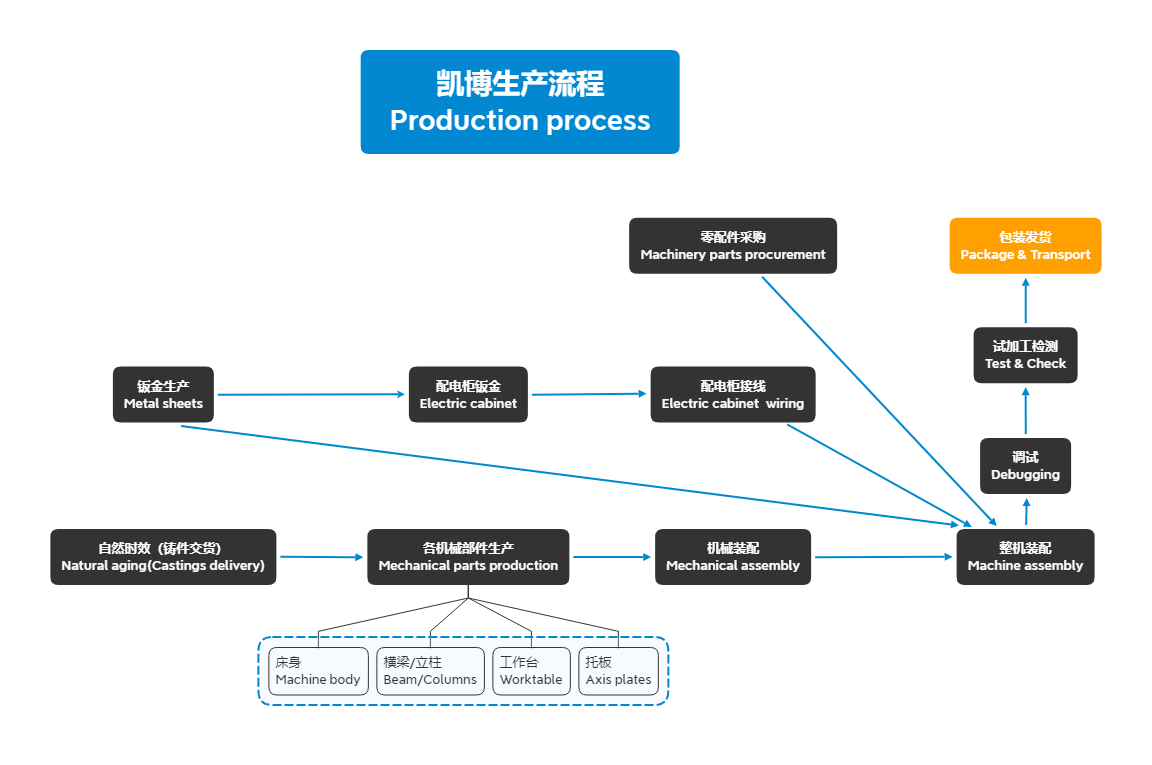

ISO9001 certification signifies adherence to internationally recognized standards for consistent quality control, process optimization, and continuous improvement. Within the context of high-end CNC milling machinery, this framework governs procedural discipline across production stages—from raw material procurement to final device calibration and packaging. It enforces a culture of traceability, accountability, and precision measurement that substantiates the machine’s capability to meet stringent engineering tolerances required in aerospace, automotive, and die & mold industries.

Through ISO9001, Kaibo CNC enables seamless integration of design parameters with manufacturing controls, making the GJ1417 a dependable asset for clients who demand unwavering part uniformity even in multi-shift operations.

The inspection process encompasses detailed examinations across three primary domains:

Performance data from these inspections are logged and cross-referenced to quickly isolate potential deviations, facilitating immediate corrective actions before shipment.

High test fidelity translates directly into operational advantages:

| Benefit | Description | Impact Metrics |

|---|---|---|

| Enhanced Part Consistency | Reducing dimensional variation in complex parts lowers scrap rates and rework. | Scrap reduction >15% within first production run |

| Minimized Unexpected Downtime | Early detection of component wear and control system anomalies prevents breakdowns. | Unplanned stoppages decreased by 20-25% |

| Improved Throughput | Faster setup times and reliable cycles increase operational productivity. | Cycle time reduction up to 10% |

Complementing its rigorous quality assurance, the GJ1417 is backed by a worldwide service framework ensuring rapid field response within 24-48 hours across major manufacturing hubs. This network empowers manufacturers to swiftly troubleshoot and resolve technical issues, substantially lowering risk exposure linked to equipment failure.

This proactive support model facilitates predictive maintenance scheduling and parts availability, reinforcing sustained production continuity and enabling users to capitalize fully on the rigour embedded during factory acceptance.